IWAKITEC Co., Ltd. (Head Office: Kamijima, Ehime Prefecture, President: Ichiro Yamamoto) has taken a major step toward welding automation. The company introduced four portable welding robots — Inrotech-Classic® models made by Denmark’s Inrotech — into its hatch cover welding line at the Innoshima Factory (Hiroshima Prefecture). Within six months of implementation, IWAKITEC successfully reduced the number of welders from 13 to 9.

Welding in shipbuilding — where each vessel has a different design — has lagged behind other industries in automation. However, the success at IWAKITEC suggests that automation in shipyard welding may soon become more widespread.

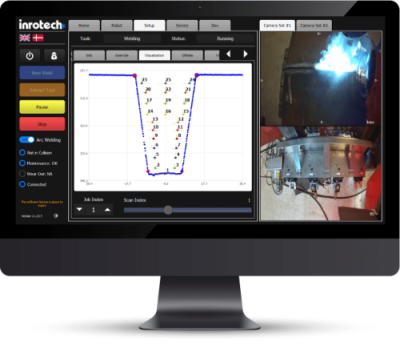

Laser-Based Seam Detection — No CAD Data Required

In May this year, IWAKITEC installed four Inrotech-Classic® units at its Innoshima plant. The robots automatically detect welding seams using laser sensors — eliminating the need for CAD data or robot programming. After setting the hatch cover materials, the operator simply enters the number of plates on the control panel (available in Japanese). No welding experience is required.

Currently, two employees (in their first and second years with the company) alternate operating the machines — though they must complete Japan’s mandatory “special education” course for industrial robot teaching operations.

The Classic robots are installed in the “L Building” hatch cover welding line — one of five assembly buildings at the Innoshima plant. A single operator efficiently manages all four robots in staggered operation, ensuring consistent weld quality.

As a result, the number of workers for hatch cover welding has been reduced from 13 to 9.

The “arc time ratio” (actual arc-on time vs. total operating time) currently ranges between 41–46%, with a target of 52% as the next improvement milestone.

Achieving Around 80% Automation

IWAKITEC first learned about Classic through an online video. After seeing it demonstrated, they met Binzel Japan (Suita, Osaka; President: Akihiro Ito) — the official Inrotech agent in Japan — at an exhibition, initiating formal discussions.

The first step was an automation rate simulation based on IWAKITEC’s hatch cover drawings.

Initially, the automation rate came out at only 33%, and the project was shelved as the ROI looked unconvincing.

However, Inrotech later proposed a new welding approach that raised the automation potential to around 80%, reopening negotiations.

The improvement came from developing an extended-arm method that allowed the robot to reach deeper weld joints on tall hatch cover walls — an area that had been inaccessible in the initial simulation.

In October 2024, Yuichi Yamaguchi, Deputy Group Leader of IWAKITEC’s DX Promotion Group, visited Inrotech headquarters in Denmark to verify the system in person. Expecting roughly 70% real automation compared with the simulation, he was surprised to see the actual performance closely matched the simulated 80%. Shortly after returning to Japan, IWAKITEC placed its order. Following training in Denmark, the system was delivered in April 2025 and began full-scale operation in May.

Real-Time Collaboration via LINE

IWAKITEC, Binzel Japan, and Inrotech have created a joint LINE group (with automatic translation), allowing all daily issues and feedback to be exchanged instantly. Inrotech’s online monitoring system also enables the robot operation data to be checked remotely from Denmark, making rapid response possible through this communication channel. Thanks to the time difference, improvements requested in Japan in the evening are often implemented by the following morning.

Six months after implementation, operations are running smoothly with only minor adjustments to materials and safety equipment. Labor-saving results have met expectations, and upward welding (PF) quality is more stable than manual work.

Toward Broader Automation in Shipbuilding

Automation in shipbuilding remains a major challenge, as few processes involve mass production.

However, IWAKITEC’s success with hatch cover welding demonstrates that automation is now viable in this field.

The company is considering introducing additional Classic units on other hatch cover lines and evaluating various automation solutions.

Notably, Classic robots are also in operation at Oshima Shipbuilding Co., Ltd. (Saikai City, Nagasaki Prefecture).

“Automation is essential to ensure that the value we deliver remains unchanged even as the workforce declines.

We had long been searching for a way to address this challenge when we discovered Inrotech’s Classic.

Other systems based on 3D CAD didn’t fit our needs, but Inrotech’s laser-based seam detection made sense for us.

Looking ahead, we need to take proactive steps now — and Classic is an investment in that future.”

President Ichiro Yamamoto, IWAKITEC Co., Ltd.

About IWAKITEC

IWAKITEC operates three main factories:

- Head Office Plant (large hull block manufacturing, Kamijima, Ehime Prefecture)

- Innoshima Plant (hatch cover production, Hiroshima Prefecture)

- Mukaishima Plant (hull block and marine outfitting production, Hiroshima Prefecture)

The company has also introduced automatic bead grinding equipment (SE-Sander by Cutland Japan).

Founded in 1957, IWAKITEC records annual sales of approximately 7 billion JPY and employs about 250 welders, including those from partner companies.