Inrotech-MicroTwin

Inrotech Microtwin | Welding robot perfect for shipbuilding

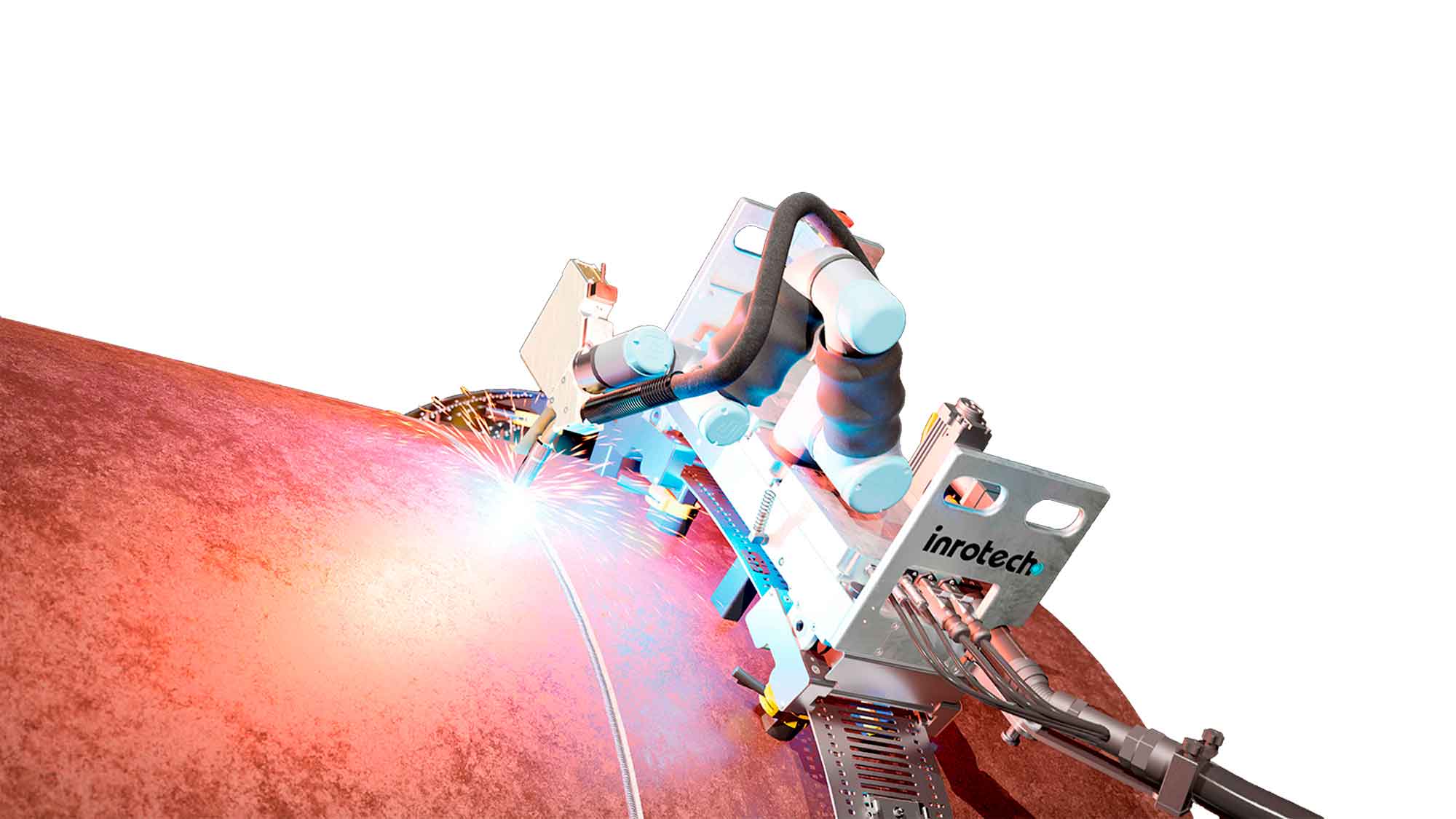

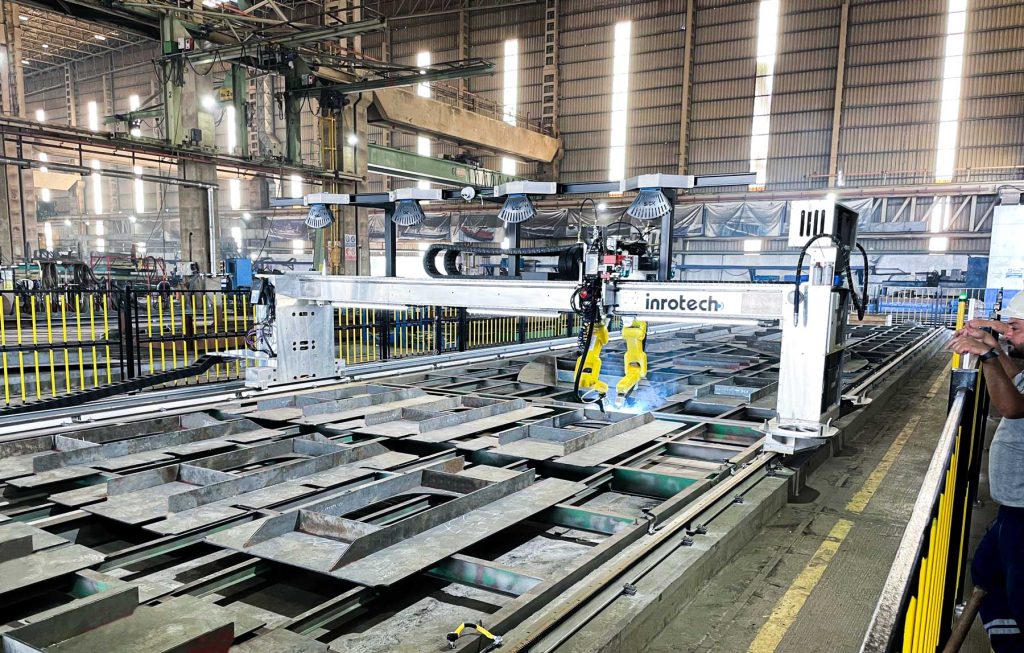

The Inrotech-MicroTwin is a compact and light weight gantry with 2 welding robots, welding machines and a scanning system for identifying stiffeners on panels. Specifically designed for the welding of micro panels, sub-assemblies and T-profiles in the shipbuilding industry, but can also be used for other purposes. Works fully automatic, push the “start” button; after completed scanning the welding starts automatically.

The operator has the option of selecting chain weld, change welding sequence etc. This is easily done on the intuitive touch panel.

The robot is delivered as a “plug-and-play” unit and is fully operational once the rails, safety curtain, or fencing, has been installed and the system has been connected to power, shielding gas and compressed air.

Inrotech-MicroTwin

GET TO KNOW OUR INROTECH-MICROTWIN

The Inrotech-MicroTwin is named as such due to the fact that two welding robots are working together – as a pair of twins.

An aluminum mini-gantry forms the basis of this welding robot system. In one of the side towers the two robot controllers are placed together with the electrical cabinet. The other side tower holds the two Kemppi A7 welding machines.

INTERESTED IN HEARING MORE ABOUT OUR INROTECH-MICROTWIN ROBOT?

NO PROGRAMMING, NO TRANSFER OF CAD-DRAWING

Not only AUTOMATIC WELDING — ALSO ADAPTIVE INTELLIGENCE

Place the items to be welded randomly within the workspace of the MicroTwin and press the start button on the intuitive touch panel. The scanning of the panels now takes place. It only takes a few minutes with a scanning speed of 36 sqm per minute.

Simpel operation

THE OPERATION OF THE INROTECH-MICROTWIN IS VERY SIMPEL

Once the scan is completed, the exact position of each profile is verified by the laser sensor, which is integrated in a housing also holding the welding gun. The welding of the profiles now takes place without any further input from the operators side. This means: Place the panels and push the start button…that’s it!

Senslogic Technology

THE ROBOT AUTOMATICALLY PLANS THE ENTIRE WELDING PROCESS

By the use of SensLogic, The Inrotech-MicroTwin scans and senses the items placed in the working area. The robot automatically plans the entire welding process, where after the welding process commences automatically. Ends are closed and vertical joints are included in the welding. As a supplementary option, Inrotech can offer the automatic detection and end closing of waterholes. The gantry can be delivered with a span of up to 6000 mm. Operation: push the green button; the gantry runs over the panels placed in the working area while making a scan. On the return way the panels are welded.

No transfer of CAD drawings, no off-line programming and no manual selection of objects to be welded. Therefore, no back-end engineers are required. The Inrotech-MicroTwin is provided with Inrotech remote-access for online support.