Heavy fabrication

SENSLOGIC & WELDLOGIC IN HEAVY INDUSTRIES

When installing Inrotech robotic solution, not only is it possible to reduce labor costs by replacing welders, but it is also possible to eliminate the need for CAD data transfer and robot teaching in heavy fabrication, which are necessary for large workpiece welding. Inrotech’s SensLogic and WeldLogic technologies offer transformative benefits for heavy industries, streamlining welding processes with unmatched precision and efficiency.

Submarines

Storage tanks

Oil rigs

Hydro power

Cranes

Bridges

INROTECH SOLUTIONS FOR STORAGE TANKS

AUTOMATED WELDING FOR STORAGE TANKS

Inrotech Robot Welding systems are designed to meet even the highest demands in the market that others simply cannot.

Automation for thick plate heavy welding on storage tanks requires careful consideration. With our systems designed to ensure the highest quality and repetitive accuracy, we offer custom and turnkey solutions to meet your ROI objectives.

Inrotech’s mobile welding solutions are optimal for the welding of these very large structures, both in the part fabrication as well (and especially) in the final assembly of the large components.

Inrotech-Crawler for the welding of storage tanks

Crane beam

INROTECH SOLUTIONS FOR CRANE STRUCTURES

AUTOMATED WELDING OF CRANE STRUCTURES

Our advanced welding technology is ideal for fabricating critical crane components. Whether it’s for mobile cranes, tower cranes, or heavy lifting machinery, our welding solutions guarantee optimal performance and compliance with industry regulations.

Enhance your crane projects with our efficient, high-quality welding services.

INROTECH SOLUTIONS FOR STORAGE TANKS

AUTOMATED WELDING OF BRIDGE STRUCTURES

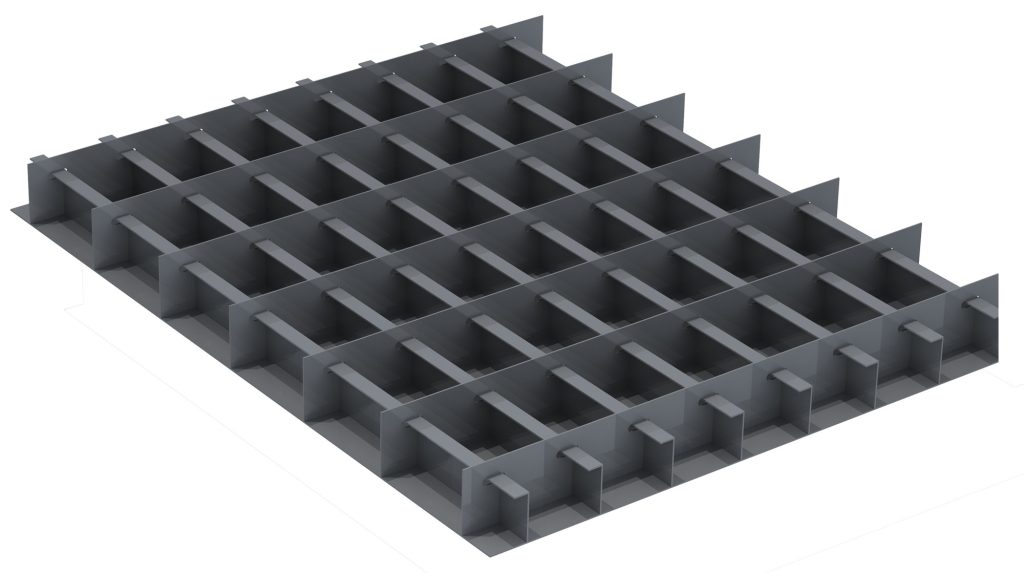

Most bridge structures can be divided into frame spacings; the space between longitudinal stiffeners and girders and transverse webs or stringers.

The Inrotech-Classic is an expert in welding such frame spacings and enables the robot to weld several of those without Offline programming and CAD data unattended one after each other by moving automatically on its rail. The operator will keep 2 up to 6 Classic robots busy across one or more open block assemblies and thereby obtain arc time ratios at several hundred percentages

Bridge structure