SensLogic

SensLogic works on a combination of scanning, sensing and a logic

SensLogic - Intelligent welding technology

SensLogic is a unique, well proven technology which initially was developed in the period 2008 to 2010. Proving its functionality successfully in various shipyards around the world, it has constantly been improved over the years ever since and represents today a unique technology platform with an unmatched simplicity and user friendliness. SensLogic works on a combination of scanning, sensing and a logic, which makes it able to identify the object to be welded automatically, as long as the design is based on design rules.

GET TO KNOW SENSLOGIC TECHNOLOGY

Beside being simple to use- you don’t have to transfer any CAD drawings or do any pre-programming- it can also to a large degree obtain tolerances as the reference is the object itself, and not a CAD drawing.

Beside the Inrotech standard products based on SensLogic, this technology can also be used for customized solutions. Combining the SensLogic technology with high level welding skills, it adds up to state-of-the-art robot welding solutions.

iNTERESTED TO LEARN MORE ABOUT OUR TECHNOLOGY PLATFORM?

NO PROGRAMMING, NO TRANSFER OF CAD-DRAWING

WHY CHOOSE SENSLOGIC TECHNOLOGY?

After the scanning sequence is completed, the Inrotech-SensLogic Technology takes over. As the 3D topography has now provided rough information about all stiffener/profile positions, the SensLogic only needs to search within a very small window to identify the size and type of the profiles/stiffener

and the exact location of each profile/stiffener including end points. This saves a lot of sensing time.

iNTERESTED TO LEARN MORE ABOUT OUR TECHNOLOGY PLATFORM?

The main advantage of SensLogic compared to other systems, which partly or fully are based on off-line programming, is that the operation runs fully automatic: No programming, No transfer of CAD-drawings, No back-end engineers required, simple green/red button simplicity, green for start, red for stop.

It is not necessary to place the robots or the workpiece in accurate positions, as the robot find out by itself. Once the set-up is prepared, the operator more or less just have to push the green “Start” button. Our philosophy is: a welding robot should not be any more complicated to use than a dishwasher.

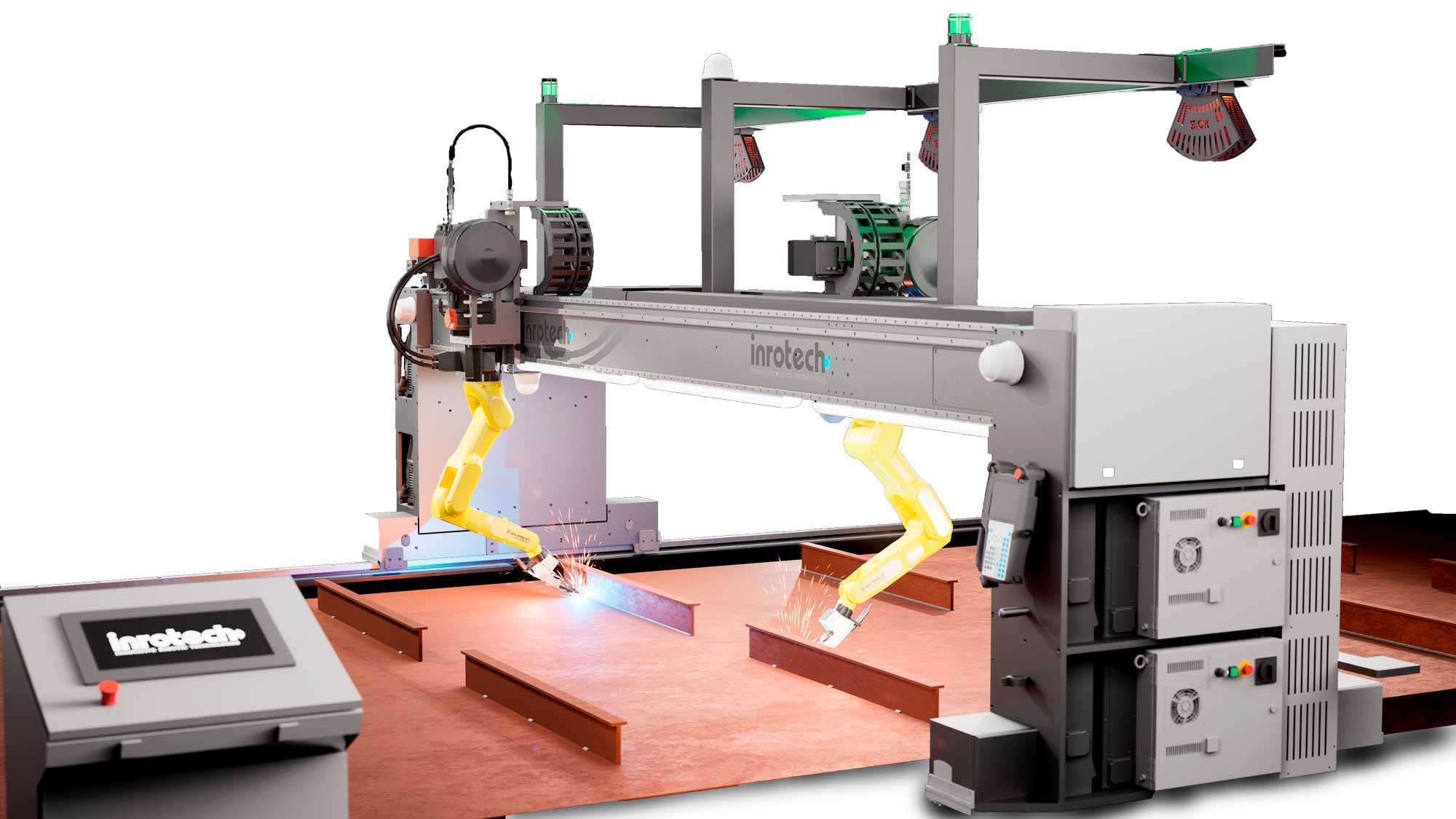

At our Gantry applications such as Inrotech-MicroTwin there is a combination high quality precision scanning with the SensLogic thus giving further autonomy to the recognition of profiles itself. The scanning process is fast, at a speed of 6m per minute over the full width of the gantry where this advanced technology is provided.

Applications with SensLogic Technology

Choose Inrotech if:

• You are welding large steel structure, in your workshop or on construction sites

• Want to robotize your welding jobs, but not to employ robot engineers

• If lack of qualified welders is a problem for you

• Want to improve welding quality

• Want to speed up cycle time

• Need welding robots to fit into your existing production lay-out

• Are looking for a trustworthy partner and not only merely a supplier

• Want to improve your bottom line

Our a way of working honours ever-important safety,

environmental and welding quality standards at their highest levels,

whilst allowing us to explore new methods and processes.