WELDING AUTOMATION TURNS COMPLEXITY INTO CONTROLLED EFFICIENCY

Liebherr Rostock, one of the leading European manufacturer of maritime handling technology, continuously seeks innovation in production processes to uphold its reputation for performance and quality. As demand surged and welding complexity grew across their product lines—particularly in the construction crane and mining equipment divisions—Liebherr Rostock sought a more intelligent and flexible welding solution.

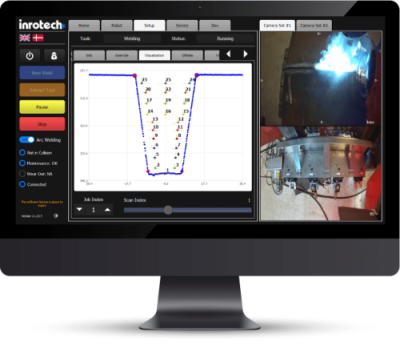

Inrotech’s fully automatic welding system, the Inrotech-Crawler™, delivered exactly that. This case study explores how Liebherr utilized the Inrotech-Crawler™ to reduce cycle times, ensure weld quality, and improve worker safety—all while maintaining exceptional adaptability across projects.

About Liebherr

Liebherr consists of over 150 companies organized into 13 product segments: earthmoving, mining, mobile and crawler cranes, tower cranes, concrete technology, maritime cranes, aerospacem, material handling technology etc.

It has a worldwide workforce over 53,000, with 14,6 billion euros in revenue for 2024.

CHALLENGE

» Manual Welding Bottlenecks: Complex

geometries and vertical welds were timeconsuming

and difficult to automate with traditional systems, leading to inconsistent quality.

» Demand for flexiblity: Projects required welding in various positions and across different component sizes—making fixed robotic solutions impractical.

» Precision and repeatability: Strict tolerances on large welded assemblies demanded accurate control of heat input and high repeatability without compromising speed.

» Workplace safety: High-heat environments

and confined spaces introduced safety challenges for manual welders.

HOW THE INROTECH-CRAWLER PROVIDED A SOLUTION

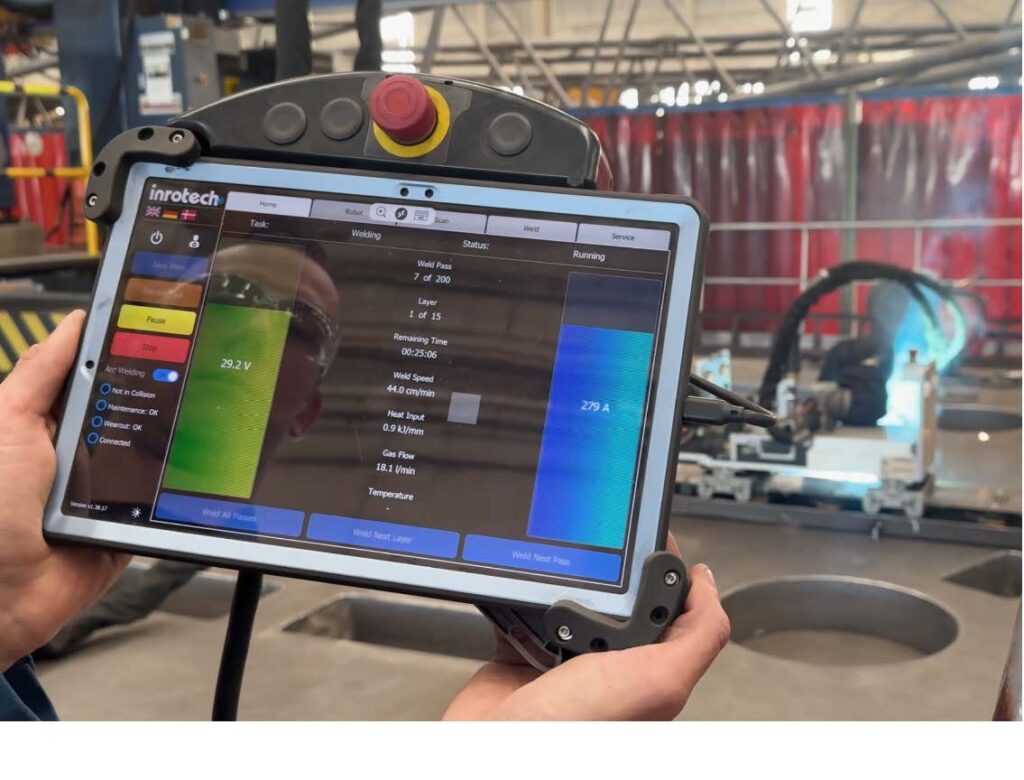

“The Inrotech-Crawler™ allows us to perform high-precision welding on components that vary in shape, size, and thickness—without the need for complicated fixtures or teaching paths.”– Florian Glamann, Welding Operations Manager, Liebherr. Liebherr integrated the Inrotech-Crawler into their welding line for heavy structural components. Unlike conventional robots requiring fixed positions and pre-programmed paths, the Inrotech-Crawler™ leverages a mobile system that autonomously detects weld seams, determines optimal welding parameters, and executes the weld—without prior CAD data or manual programming.

With Inrotechs WeldLogic technology the heat input are planned and controlled to stay below the WPS limits and the arc-on time can be 70-90% of the operation time, also on shorter welds resulting in higher depositions rates. Furthermore, a multi job mode can facilitate the robot to execute more welding jobs in parallel, allowing the interpass temperature to drop while another welding is being performed.

“Utilizing laser scanners and the WeldLogic weldplanner software, the robot will automatically adjust the welding parameter, to adapt to varying tolerances and deformations, occurring during welding. The result is an unsupervised operation, which will free the operator, to attend to other tasks, e.g. starting up more robots in parallel.”- Florian Glamann.

WHY LIEBHERR CHOSE INROTECH

- Autonomy: The system requires no teaching or CAD input. It adapts to realworld variations and welds accordingly.

- 85% reduction in welding cycle time

- 60% reduction in setup time

- Portability: Compact and self-contained, the Crawler moves freely across large workpieces and confined spaces, performing high-quality.

- Compatibility with Existing Workflows: The robot is integrated into Liebherr’s existing infrastructure with minimal downtime.

- High Repeatability and Quality: The WeldLogic technology ensures precision even with groove variations. If the groove geometry changes during the weld, due to deformation, WeldLogic detects this, and change the welding parameters accordingly.

- Proven Reliability: Built for harsh industrial environments, the Crawler delivers

consistent uptime and durability in demanding conditions.

LOOKING TO ENHANCE YOUR WELDING PROCESSES?

At Inrotech, we combine cutting-edge robotic welding technology, deep industry expertise, and scalable solutions to meet the demands of modern manufacturing. Our intelligent systems are designed to streamline your production processes, reduce bottlenecks, and deliverconsistent, high-quality results.