Orbital welding machines and the Inrotech-Crawler solve fundamentally different problems with different kinematics, sensing, process envelopes, and productivity models. Orbital systems are purpose-built to rotate a weld head around a cylindrical joint—typically pipe or tube—under tightly controlled, largely uniform conditions. The Inrotech-Crawler is a mobile, multi-axis robotic welding platform that navigates long, irregular seams on large plate and profile structures, continuously sensing and adapting to geometric variation and distortion. Calling the Crawler “orbital” is technically inaccurate; it neither orbits a workpiece nor is it constrained to circular joints.

The difference

Orbital welding

- Primary geometry: circular joints (pipe-to-pipe, pipe-to-fitting).

- Motion topology: a weld head performs a 360° revolution around the joint centerline (or the pipe rotates under a stationary head).

- Joint types: square butt / V-prep on tubes; often thin- to medium-wall.

Inrotech-Crawler

- Primary geometry: long straight or curved seams on plates, stiffeners, T-joints, fillets, and butt joints across large fabrications (hulls, decks, girders, wind and offshore modules, heavy steel structures).

- Motion topology: the robot translates along the seam with multi-axis torch manipulation; there is no rotational “orbit” about the workpiece.

- Joint types: fillet, lap, T-joint, butt (single/multi-V), variable gaps, changing fit-up, and multi-pass grooves.

Implication: Orbital = one circular degree of freedom around a pipe. Crawler = multi-axis seam-following across meters (often tens of meters) of non-circular geometry.

Kinematics and sensing

Orbital machines

- Typically one principal path axis (rotation) plus controlled torch parameters; some heads add AVC (arc-voltage control) and limited seam tracking within a narrow envelope.

- Workpieces are highly fixtured and aligned; repeatability relies on consistent pipe prep and purging.

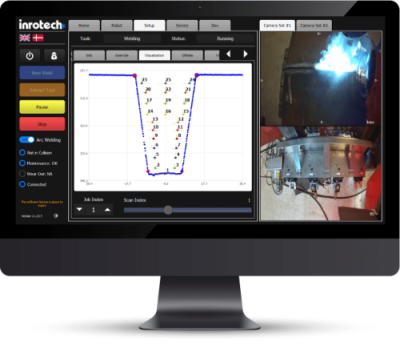

Inrotech-Crawler with WeldLogic™

- Multi-DOF torch manipulation and carriage motion for torch angle, stick-out, oscillation/weave, and travel speed control.

- WeldLogic sensing loop:

- Scan the real seam with laser/camera sensors to locate edges and groove geometry.

- Plan the path (torch angles, weave width, pass count, tie-in strategy) based on actual measurements.

- Weld with real-time adaptation to gap variation, part distortion, and heat input limits.

- Verify and log parameters for traceability.

- Designed to tolerate imperfect fit-up typical of shipyards and heavy fabrication.

Implication: The Crawler’s control loop is built for spatial and geometric variability; orbital heads assume a uniform circular track with comparatively limited variation.

Process envelope and metallurgical goals

Orbital

- Often GTAW/TIG (sometimes GMAW) is prioritized for high-purity, low-spatter applications (semiconductor, pharma, food, high-spec piping). However, there are more orbital welders working on cross-country pipelines than in nuclear applications, with FCAW and GMAW being the most common processes—roughly a 2-to-1 ratio of field units designed for CC (cross-country) work versus nuclear.

- Narrow-groove TIG can reach up to 2” in wall thickness. For this type of joint, an orbital welder is essentially the only viable solution unless you have a ‘golden-glove’ TIG welder, of which only a few exist worldwide.

Crawler

- Optimized for GMAW/MAG/FCAW with high deposition rates, controlled heat input, interpass temperature management, and multi-pass filling of heavy sections.

- The Crawler can also weld around pipes, but only from a diameter of approximately Ø2.3 meters and above, where the geometry is large enough to accommodate the system.

The Crawler is a heavy-fabrication productivity system; orbital is technically a precision circular-joint system for cross country pipeline work.

Setup, fixturing, and production model

Orbital

- Requires precise pipe end-prep, clamping, and an orbit-capable head sized for the diameter range.

- Purging and cleanliness are central; cycle time measured in joints per shift.

Crawler

- Uses rails or guided motion along the structure; references edges and seams in situ.

- Minimal global fixturing; manages meters of weld per shift across many joint types.

- Pass planning (via WeldLogic) automates bead placement across changing groove depths and widths.

Implication: Productivity metrics are not directly comparable (joints/shift vs. meters/shift; thin-wall precision vs. heavy multi-pass throughput).

Quality control and traceability

Both can log parameters and support WPS compliance. However, their QC realities differ:

- Orbital: parametric repeatability on a circular path; purge quality and alignment dominate.

- Crawler: path- and pass-aware logs over long seams; geometry maps, adaptive corrections, restart/crater data, and interpass control are integral to quality.

6) Typical mislabeling: why “orbital” is inaccurate for the Crawler

- “Orbital” specifically means the torch orbits the joint.

- The Inrotech-Crawler does not rotate around a cylindrical workpiece; it tracks along a seam on large structures with multi-axis adjustments.

- Its core advantage—WeldLogic® adaptive planning and real-time correction across non-uniform geometry—is unrelated to orbital rotation and would not be exercised by an orbital head.

7) Application guidance

Choose an orbital welding machine when you need:

- Circular pipe/tube joints, often with stringent hygienic or purity requirements.

- GTAW-grade surface quality inside/outside with controlled purging.

Choose the Inrotech-Crawler (WeldLogic®) when you need:

- High-productivity, long-seam welding on plates and profiles (fillets, T-joints, butts).

- Robust performance on variable fit-up, changing gaps, and thermally induced distortion.

- Multi-pass groove filling with automated pass planning and continuous adaptation.

- Scalable throughput over large fabrications (shipbuilding, offshore, heavy steel).

Conclusion

Orbital welding machines and the Inrotech-Crawler inhabit different worlds. Orbital systems specialize in rotational, circular joints—a narrow but critical niche. The Inrotech-Crawler, powered by WeldLogic, is a mobile, adaptive, multi-axis solution for long, complex seams on large structures where geometry varies and productivity matters. On technical grounds—kinematics, sensing, process control, and application scope—the Crawler is not comparable to an orbital welding machine. It is a different class of automated welding system designed for a different class of work.

However, adding WeldLogic™ to an orbital solution would enhance consistency on pipelines or pressure vessels with variable fit-up– Compensating for out-of-round pipes and variable wall thickness– Automatically adjusting fill levels to reduce consumable waste– Maintaining consistent quality across misaligned or imperfect fit-ups.