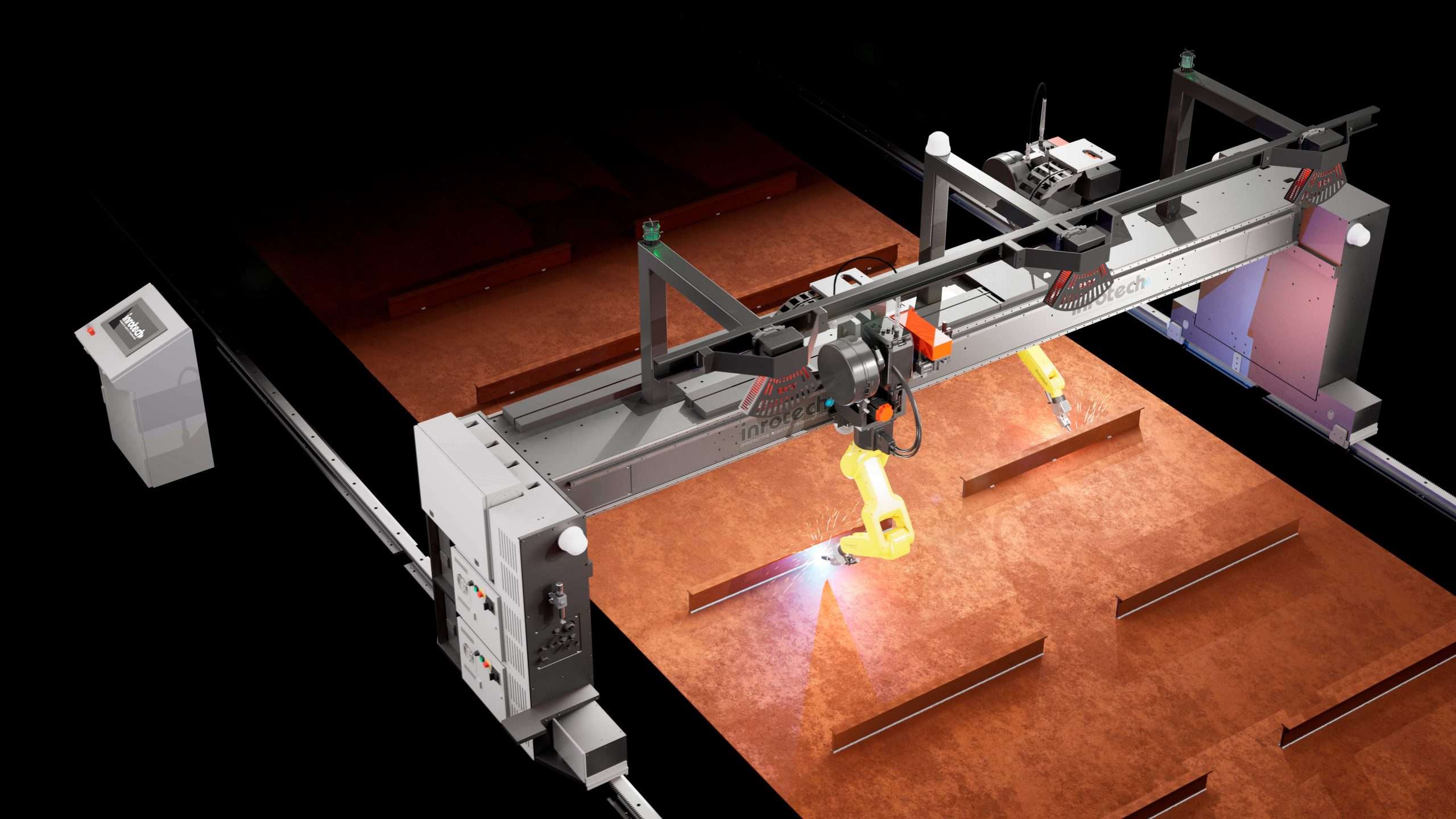

The Inrotech-MicroTwin is purpose-built for the automated welding of micro/mini panels, sub-assemblies, T-beams, and small parts. It eliminates the need for programming or CAD file transfers, as well as the selection of macros or intermediate programming based on scans or photos. As a result, back-end engineers can focus on other tasks. The Inrotech-MicroTwin is delivered as a “plug-and-play” unit, ready for operation.

3 SIMPLE STEPS TO COMPLETE THE ENTIRE WELDING PROCESS

This video demonstrates that the operator only needs to give the HMI 3 inputs before initiating the entire welding operation.

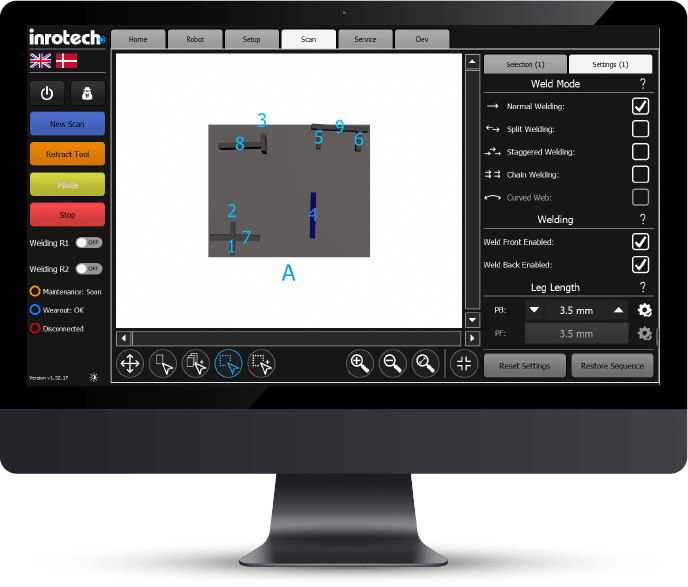

SENSLOGIC TECHNOLOGY

The foundation of the system relies on the highly reliable Inrotech-SensLogic Technology. Prior to the activation of Inrotech-SensLogic Technology, high-resolution overhead line scanners are employed to scan the panels arranged in the working area, generating a 3D topography. This topography offers comprehensive insight into the positioning of each profile/stiffener.

Following the completion of the scanning process, Inrotech-SensLogic Technology takes charge. With the 3D topography providing details about all stiffener/profile positions, SensLogic operates within a small window to precisely identify the size and type of profiles/stiffener, along with their exact locations, including end points, significantly reducing sensing time. SensLogic employs a blend of sensing (via the laser sensor integrated into the housing with the welding gun) and logic.

All commands are articulated in clear language and supported by icons, eliminating the need for programming or specialized skills.

The integration of Inrotech-Scanning and -SenLogic distinguishes the Inrotech-MicroTwin from other Micro Panel welding solutions in the market, with patent pending.

GENERAL PROCESS & OPERATION

The initial step requires the operator to visually confirm that the welding area is clear and accessible. The operation is activated by a straightforward action: pressing the “Start” button located on the touch panel.

The Inrotech-MicroTwin smoothly traverses the panels positioned within the working area while conducting a thorough scan. This scanning process generates a 3-dimensional topographic representation of the panels, providing insight into the structure of the welding tasks and forming the basis for defining welding sequences, start-stop points, and more.

Upon completion of the scanning process, the system seamlessly initiates welding without further intervention from the operator. Utilizing sensor technology and the integrated SensLogic, the system can execute the welding of micro panels with longitudinal and transitional stiffeners, including vertical joints, without the need for manual programming.

INROTECH REMOTE SERVICE

All Inrotech robot systems come equipped with Inrotech-Remote Service (IRS), a secure access gateway from Secomea. Secomea’s Sitemanager adheres to the highest global cybersecurity standards and aligns fully with Industry 4.0 criteria. It facilitates both remote access and data collection within a single unit. Operators can conveniently monitor the robot’s movements via various cameras and access welding machine parameters.

Communication with the Inrotech robot occurs exclusively through the secure access gateway, effectively isolating the robot system from the client’s network. This grants Inrotech the autonomy to determine the structure and configuration of elements within the closed network of the robot system. Additionally, it eliminates the necessity for remote access via the client’s VPN.